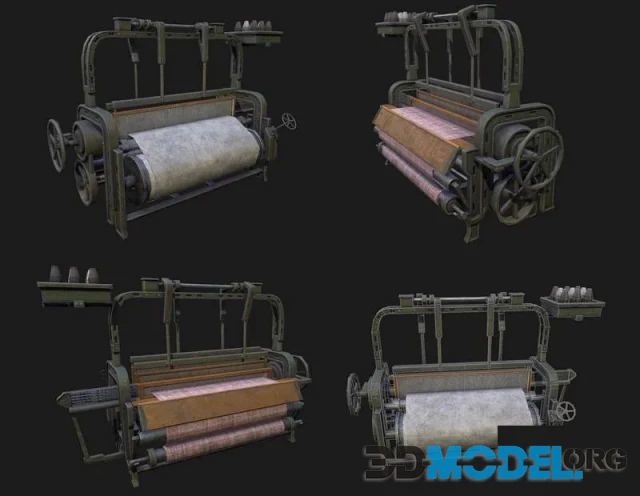

WWII rolling machine (PBR)

America's entry into World War II marked the beginning of an era in American defense manufacturing. To manufacture planes, tanks, trucks and guns for combatting Axis powers, it invested both financial and intellectual resources. Furthermore, atomic weapons were developed as part of this effort.

By the end of World War II, American military manufacturing had become a dominant force in war machine production - producing more naval tonnage than Japan had produced throughout its entire conflict. By then, more than half of all industrial production had taken place within America alone.

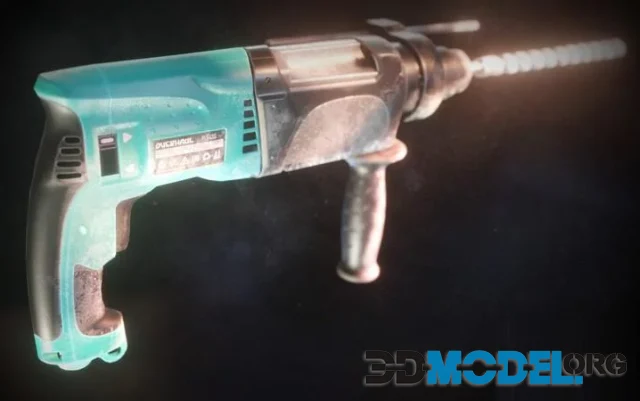

To fabricate sheet metal, metalworking companies first heat raw metal in a large furnace until it reaches a molten state. After cooling, the metal is then poured into an ingot-shaped mold and allowed to cool. Finally, the raw metal is fed through rolling machines equipped with two rollers that compress it into thinner, more uniform pieces of metal.

Wire train of rolls are more compact than standard rolling machines, with threading inside the machine for reduced material loss and worker safety. Furthermore, these trains of rolls are easier to operate and dependable - which increases productivity.

During World War II, millions of women transitioned into jobs previously only available to men - such as mechanics, welders and aircraft assembly workers. This shift freed men up to fight in the conflict while stimulating economic activity at home.

Quality 3d-model with PBR-textures in the archive.

File type: MAX, FBX, OBJ

Ctrl

Enter

Noticed a misTake

Highlight text and press Ctrl+EnterRelated news:

Comments (0)